Views: 0 Author: Site Editor Publish Time: 2024-08-14 Origin: Site

In the bustling world of industrial operations, ensuring the safety of workers and the integrity of machinery is paramount. One of the unsung heroes in this domain is the humble label. But not just any label—specific label materials designed for safety protection are crucial. Are your label materials for safety protection up to standard? Let's delve into why this is a question you should be asking yourself regularly.

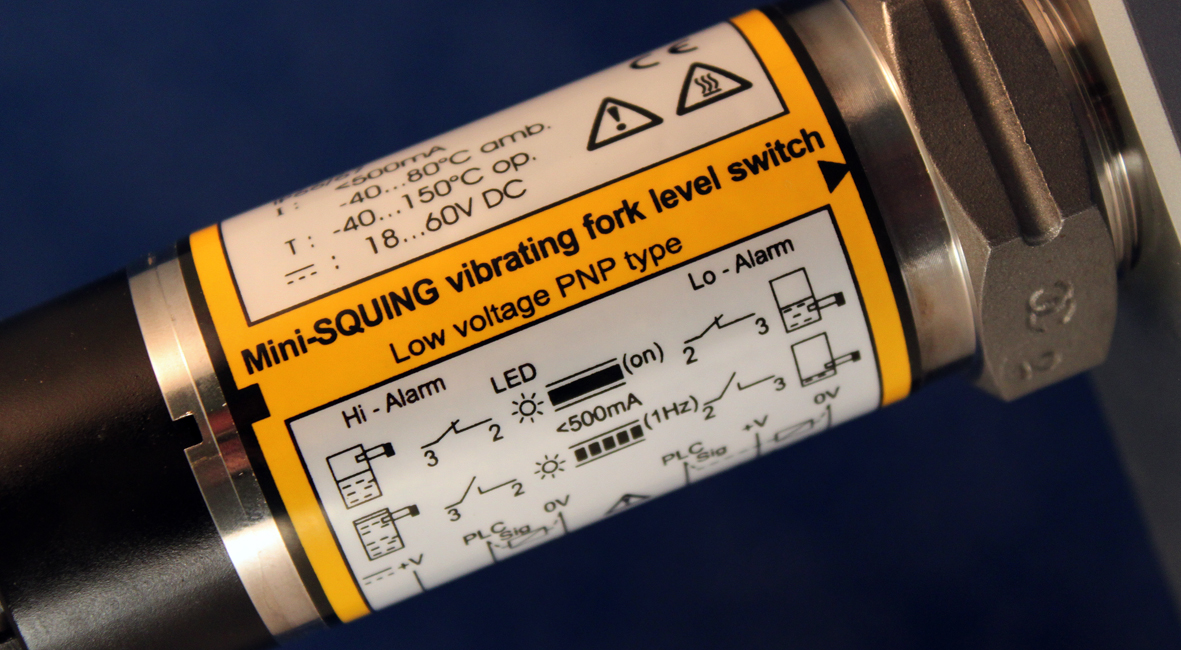

Label materials are more than just sticky notes slapped onto surfaces. They serve as critical communication tools, providing essential information about mechanical identification, operational instructions, and potential hazards. In environments where safety is a priority, the quality and durability of these labels cannot be compromised.

Mechanical identification is a key aspect of industrial safety. Labels used for this purpose must be able to withstand harsh conditions, including exposure to chemicals, extreme temperatures, and physical abrasion. High-quality label materials ensure that the information remains legible and intact, thereby preventing accidents and ensuring smooth operations.

Safety protection labels need to meet stringent standards to be effective. Here are some attributes to look for:

Durability: The label material should be resistant to wear and tear, ensuring longevity.

Legibility: Text and symbols must remain clear and readable under various conditions.

Adhesion: The label must stick firmly to surfaces without peeling off easily.

Compliance: The materials should meet industry-specific safety standards and regulations.

Several types of label materials are commonly used for safety protection, each with its own set of advantages:

Vinyl: Known for its flexibility and durability, vinyl is a popular choice for safety labels.

Polyester: This material offers excellent resistance to chemicals and extreme temperatures.

Polycarbonate: Ideal for environments requiring high impact resistance.

Paper: While less durable, it is suitable for temporary labeling needs.

Ensuring that your label materials meet the required standards involves regular audits and updates. Consult with suppliers who specialize in safety protection labels to get the best materials for your specific needs. Additionally, stay updated with industry regulations to ensure compliance.

In the grand scheme of industrial safety, label materials may seem like a small detail, but their impact is substantial. From mechanical identification to safety protection labels, the right materials can make all the difference. So, take a moment to evaluate whether your label materials are up to standard. Your commitment to quality and safety could very well save lives and protect valuable assets.